In-house calibration services refer to the process of performing the calibration and testing of a company’s instruments and equipment on-site rather than outsourcing the services to an external provider. This type of service is becoming increasingly popular for many companies as it allows for greater control over the calibration process, resulting in more accurate results and improved efficiency. In-house calibration services are often used to ensure that calibration instrumentation and equipment are operating within specified tolerances and to provide assurance that they are performing as expected.

There are a number of advantages to using in-house calibration services. One of the primary benefits is that it allows for more control over the calibration process because the calibrations are performed by technicians employed by the company. This allows for better communication between the technicians and the personnel responsible for the calibration and also provides an opportunity to ensure that the instruments and equipment are functioning correctly. Additionally, in-house calibration services can be more cost-effective than outsourcing the services to an external provider, as the company can take advantage of the economies of scale associated with performing the calibrations internally.

In-house calibration services also allow for the calibration technician to be readily available to answer questions, resolve any issues that may arise during the process, and provide technical guidance as needed. This can save time and money in the long run, as the technician is able to provide timely assistance as needed. Additionally, the technician can also provide advice on how to maintain the instruments and equipment and when calibrations may be necessary.

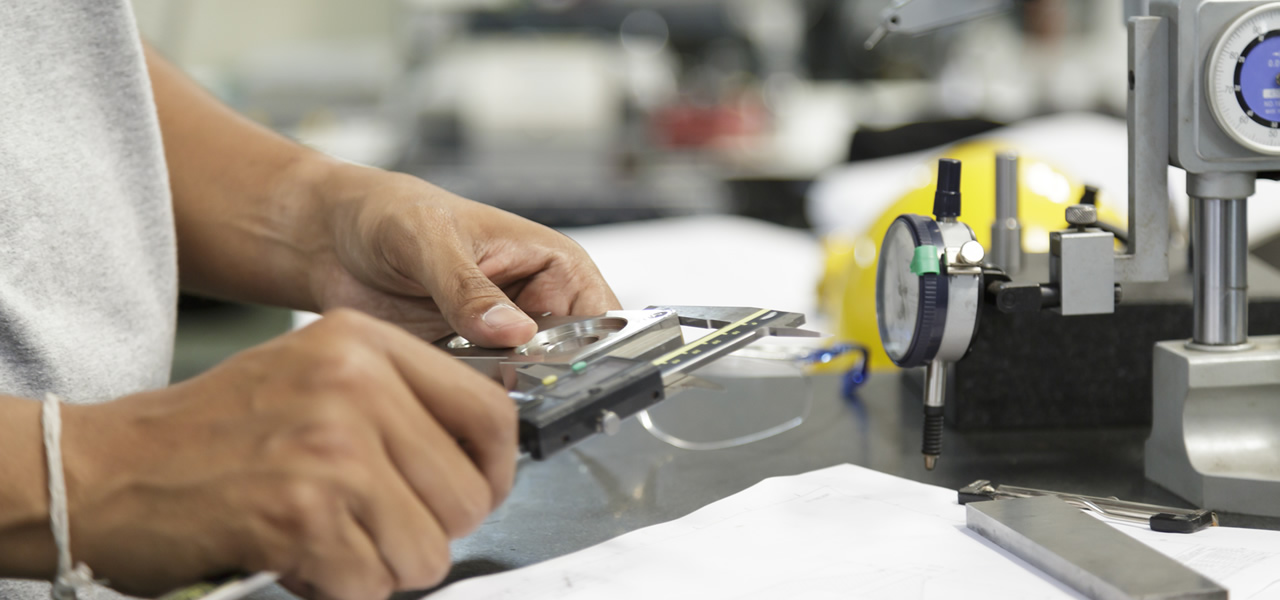

As with any calibration process, there are a number of steps involved in in-house calibration services. The first step is to identify the instruments and equipment that require calibration. This is done by performing a survey of the instruments and equipment and determining which need to be calibrated. After this has been done, the next step is to select the appropriate calibration equipment and procedures that will be used. This includes selecting the calibration equipment and determining the necessary tests and measurements that will be performed.

Once the calibration equipment and procedures have been selected, the next step is to perform the actual calibration. This involves connecting the calibration instrumentation to the instruments or equipment and performing the necessary tests and measurements. Once the calibration is complete, the results are documented, and the instruments and equipment are adjusted as necessary. Finally, the calibration is verified, and the technician is able to provide a final report on the accuracy of the calibration.